Kenya’s apparel sector needs to close the loop. Over 400,000 tons of cotton waste are produced annually in Kenya by the apparel industry.

Global climate targets may or may not be achieved due to the fashion sector. Being the second-largest consumer of water, the sector is responsible for 4 to 10 percent of world emissions.

Being the second-largest consumer of water, the sector is responsible for 4 to 10 percent of world emissions.

A persistent increase in the world’s gross domestic product (GDP) has raised incomes everywhere, encouraging customers to buy new clothes more frequently, which could make the situation worse.

To keep warming to 1.5 degrees Celsius, the industry must cut emissions by 45 percent in absolute terms by 2030. Without quick action, emissions will yet increase to 1.588 gigatons by 2030.

To accomplish this reduction in emissions, the industry will need to address the substantial amount of garbage it generates. One factor is post-production textile waste, since up to 20% of the fabric used to make garments is lost. Via transportation to landfills or emissions emitted during the burning of textiles, this garbage generates its own emissions.

Waste management presents particular difficulties in East Africa. The area generates a sizable portion of the world’s textile manufacturing, which results in a sizable amount of post-production trash.

An estimated 400,000 tons of cotton waste are produced by the clothing industry each year in Kenya.

Despite having the ability to recycle materials, manufacturers do not have circular waste-to-value solutions that preserve the value of textiles. Because of this, textiles are frequently transformed into inferior materials with limited usefulness, such as floor mats, pillow filling, and insulation material.

Waste reduction strategies that are revolutionary are required for the apparel industry in East Africa and beyond.

Successful implementation of these solutions is being demonstrated by one partnership in Kenya.

As other nations transition their fashion businesses toward more sustainable practices, their work may offer important lessons for them.

As a result, both the global climate goals and economic growth will be aided by this change.

A New Alliance Is Altering The Fashion Industry.

A middleman who can transform trash into sustainable raw materials for the manufacture of new garments is necessary to reduce waste across the supply chain, from manufacturing to recycling.

Closing the Loop on Textile Waste in Kenya fills that need.

They make use of a cutting-edge chemical recycling process created by the American company PurFi, which turns textile waste into high-quality products that can be recycled again and again in fresh production.

To reduce waste, the fashion industry in East Africa and beyond needs innovative solutions.

Compared to conventional methods for recycling textile waste, this system utilizes 99 percent less water, up to 90 percent fewer greenhouse gas emissions, and 90 percent less energy.

More than 15,000 chemicals, some of which are toxic, are involved in the production of clothing, so chemical use itself is not environmentally friendly; however, PurFi’s cutting-edge rejuvenation technology maintains a closed process that absorbs the recycling chemicals back into the resulting fabric.

The collaboration not only has positive effects on the climate but also shows how social fairness and environmental impact are intertwined. They provide training to previously unemployed women in the neighborhood, assisting in securing fair and secure employment that enables them to support their families.

The 36,000 kg of rubbish that this all-female sorting staff processes each month is being increased to 100,000 kg each month.

The collaboration has thus far sold 100,000 kg of textile cotton waste collectively.

A successful 2018 project from India served as the foundation for this multistakeholder program, which is being managed by the nonprofit Enviu and includes PurFi and Upset Sourcing East Africa.

The absence of recycling options and rising textile manufacturing in Kenya provided the ideal setting for the cooperation to imitate India’s model.

The Global Goals 2030 (P4G) and Partnering for Green Growth (P4G) State-of-the-Art Partnership Awards honor the most significant collaborations worldwide that are advancing new business models each year.

For its efforts to revolutionize textile recycling throughout Africa, Closing the Loop on Textile Waste received the Partnership of the Year for 2021 award, which was presented at COP26.

The future of Kenya’s fashion industry and Closing the Loop

The work of Closing the Loop is taking place at a crucial juncture as Kenya’s significance in the fashion sector is rising quickly.

Kenya’s Big Four Strategy, which places an emphasis on job creation in the manufacturing sector and raised living conditions, lists the restoration of the local textile industry as one of the country’s top priorities.

The expansion of textile manufacturing for export has also been encouraged by recent trade agreements and the establishment of special economic zones.

As a result, it is anticipated that over the next five years, Kenya’s export of textiles and apparel will rise by 25% annually.

Even though Kenya’s textile sector will increase significantly, post-production waste is already amassing as a result.

With two crucial strategies, the collaboration is seeking to develop alongside the sector and include recycling methods in the supply chain:

1. Public-private Partnership

Closing the Loop has a unique potential to assist both government organizations and clothing manufacturers in addressing the problem of textile waste thanks to their waste-to-value solution.

The Ministry of Industrialization, Trade, and Enterprise Development in Kenya’s Export Processing Zone Authority (EPZA), which is in charge of fostering export-oriented business projects, has been enlisted by the collaboration.

To manage the enormous amounts of textile waste produced by large clothing manufacturers inside their agency, EPZA needs viable and circular solutions. 450 new production lines are being built simultaneously inside EPZA, which will increase the amount of waste generated after production.

Closing the Loop can help EPZA by working together to give the agency the circular solutions they now lack. As a result of the partnership’s access to the textile waste produced by both old and new production lines, they will be able to recycle even more materials.

Meanwhile, in Kenya, waste management firms and producers have entered sourcing agreements with the collaboration. The collaboration is able to accurately track waste across their supply chain by developing an extensive connection with vendors. Given the intricate network of middlemen that source and produces items, product traceability is frequently challenging. In order to better reduce and recycle garbage, the collaboration will be able to better identify the areas where it is produced by collaborating closely with a variety of firms.

2. Scale And Efficiency Improvements

Via its partnerships, Closing the Loop will be able to access and recycle more waste than ever before. On the other hand, the collaboration will need to operate more effectively and on a greater scale in order to be able to process such a large volume of waste. In light of this, Closing the Loop intends to grow by moving to a bigger location where it will have access to more tools, staff members, and post-production materials. The alliance will be able to sift the enormous volume of rubbish they will receive as a result.

Solving environmental difficulties in textile production will not only mitigate climate change but also give a $192 billion total boost to the world economy by 2030.

Extending their work will have financial advantages for the partnership and the areas they serve in addition to significant trash reduction. The price per sorted kilogram of waste will decrease as waste volume from suppliers is increased and sorter output is increased. Additionally, this will enable the collaboration to keep creating socially just jobs and support Kenya’s Big Four Agenda.

In the long run, Closing the Loop intends to spread its technology throughout Kenya and create a network of strong, neighborhood textile waste centers. Recycled post-production waste would be given back to the original producers by this network. They would then make it possible for waste to flow continuously for regeneration.

If the agreement is successful, it will significantly aid Kenya’s textile industry in making the shift from its current inefficient informal waste methods to a formal circular system.

Establishing A Globally Sustainable Fashion Business

The Closing the Loop on Textile Waste effort demonstrates that it is feasible to transition to circular textile waste management, promote social fairness, and generate employment in the areas where the sector has the most negative effects.

This all-encompassing model shows how local solutions can contribute more to the shift to sustainable practices. Moreover, some solutions may have significant advantages: By 2030, addressing environmental issues in the textile industry would help the world economy gain $192 billion in benefits in addition to reducing climate change.

P4G is creating a network of collaborations that, like Closing the Loop, turn trash into a resource for the textile, plastic, and food industries.

Completing the Loop builds on the synergies with P4Circular G’s Fashion Partnership, which brings brands, producers, and recyclers together to improve the value of trash by recycling it into new textile products in Bangladesh. These partnerships have the ability to increase their impact, increase transparency, and track waste throughout the global fashion chain by cooperating and exchanging lessons learned about textile reuse and recycling around the world.

The world needs more cutting-edge business models that can quickly change established processes. These models can be advanced through partnerships across the supply chain, but only with backing from financiers and participants in the fashion industry. They can attain the scale and collaboration required to develop a truly sustainable fashion sector if they take Closing the Loop’s lead.

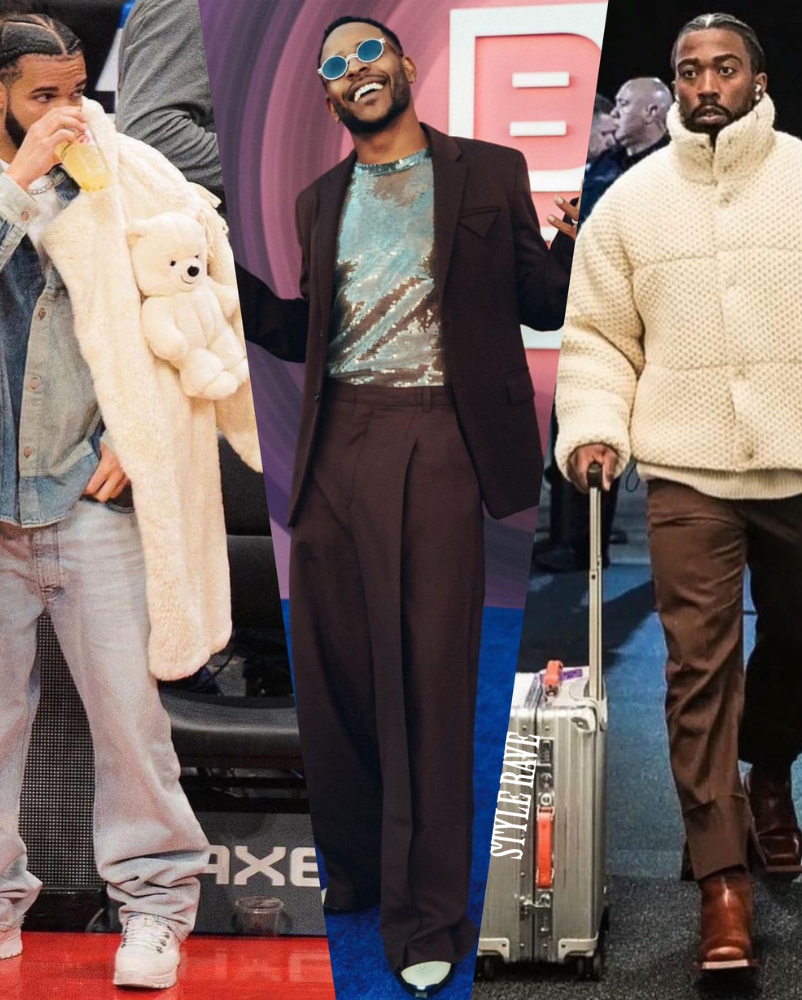

Photos Credit Shop Zetu & African Yuva

Content courtesy of World Resources Institute, Green Biz & NFH

Related